The next is really a sample application utilized to illustrate the typical method for deciding on a Disc coupling. Any resemblance to any current company?¡¥s application is neither intentional nor meant to resemble that company?¡¥s real application.

Sample Application:

A company features a compressor application working with a 225 horsepower electrical motor running at one,150 RPM to drive a three cylinder multi stage reciprocating air compressor. The electrical motor has a 3-3/8 inch shaft with a 7/8 inch keyway and the compressor has a 92mm shaft by using a 25mm keyway. The shaft separation is approximately 7 inches between shaft ends with some capability to alter the motor area. The shafts have a parallel misalignment/offset of roughly 1/32 of an inch.

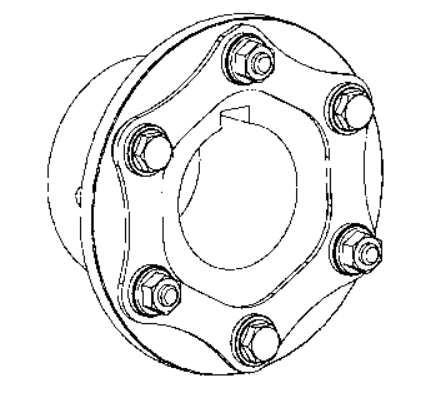

Phase 1: The very first stage would be to identify what coupling type is to be selected for this application. Since the SU Variety coupling only supports

just one flex plane, it may possibly only accommodate angular and axial misalignment, but not parallel misalignment. The following alternative can be to look at an SX or DI Type coupling. The 6 bolt SX Style will accommodate each parallel misalignment plus the defined shaft separation. The dimension will probably be established through the choice torque as well as shaft diameters.

Step 2: Subsequent, determine the application torque and apply the service issue to determine the selection torque.The formula utilized to determine torque is as follows:

Application Torque ( in¡§Clb ) = ( HP x 63025 )/RPM

or Nm = ( KW x 9550)/RPM

Plugging in the numbers in the application description:

Application Torque ( in-lbs ) =(HP x 63025)/RPM = (225 x 63025)/1150 = 12,331 in-lbs

Application Torque x Services Component = Choice  Torque

Torque

twelve,331 in-lbs x 3.0 = 36,993 in-lbs

Phase 3: Use the SX coupling tables and note that the SX 202-6 is rated at 40,700 in-lbs, greater than sufficient to deal with the variety torque calculated in phase 2. The SX202-6, nonetheless, won’t assistance the 92mm shaft size. The subsequent greater dimension coupling, the SX228-6, will support the 92mm shaft size along with the shaft separation dimension (BSE) is six.88 inches, quite close to the application?¡¥s desired 7 inch separation. The SX228-6 is rated at 62,000 in-lbs which may seem to be extreme, however, the coupling size is critical to handle the bore size.

Step 4: The SX228-6 coupling is rated for a maximum unbalanced pace of 3,400 RPM, a lot more than adequate to support the application speed of 1,150 RPM.

Step 5: To determine in case the coupling will handle the parallel misalignment, use the trig perform of tan 1?? = offset permitted for 1 inch = 0.0174

Multiply the 0.0174 x the distance amongst disc packs or ??S?¡¥ dimension through the table on web page D-13, or five.50 inches.

The allowable parallel offset is 0.0174 x 5.50 = 0.096 inches. The utmost offset for the application is 1/32 inches (0.031), as a result this coupling can accommodate the parallel misalignment.

Note: It’s always recommended to make an effort to install the coupling at approximately 20% in the allowable misalignment. For this coupling the installer really should endeavor to realize improved than 0.020 parallel misalignment in the time of installation. This can let for that further misalignment that should take place since the outcome of tools settle and standard equipment dress in.