flexible gear coupling

As one of leading flexible gear coupling manufacturers, suppliers and exporters of mechanical products, We offer flexible gear coupling and many other products.

The diaphragm coupling has a strong ability to compensate the misalignment of the two axes. Compared with the gear coupling, the angular displacement can be twice as large. When the radial displacement occurs, the reaction force is small and the flexibility is large. It allows certain axial, radial and angular displacements.

flexible gear coupling

Popular products

flexible gear coupling

The high tooth contact and high-quality gearing create high torsional rigidity.

Low restoring forces are imparted while compensating for shaft misalignment.

The special geometry of the gearing also allows for large offset values during operation – whether they be lateral, angular or axial.

Secure torque transmission is achieved by precision shoulder bolts with fine threads

The low-wear, flexible gear couplings from EP are used in a wide variety of industries. Particularly in heavy-duty operation – such as on the high torque shafts of mixers, rolling mills, crushers, test stands and conveyors – gear couplings transmit torques from 1,900 to 2,080,000 Nm with high torsional rigidity and low backlash. To ensure optimal performance, EP manufactures both the coupling hubs and the flange sleeves with precise crowned gearing, made from high-strength steel.

flexible gear coupling

EP Curved Tooth Flexible Gear Couplings are made for extensive use in Metal Rolling Mills, Paper Machinery, Cranes, Dredgers, Rubber and Plastic Industries, Cement Plants, Conveyors and Elevators, Compressors, Fans and Blowers, Screens and other general industries.

EP Gear Couplings are distinguished by their mechanical flexibility and compensation of Angular, Parallel and Axial misalignments of the connected shafts.

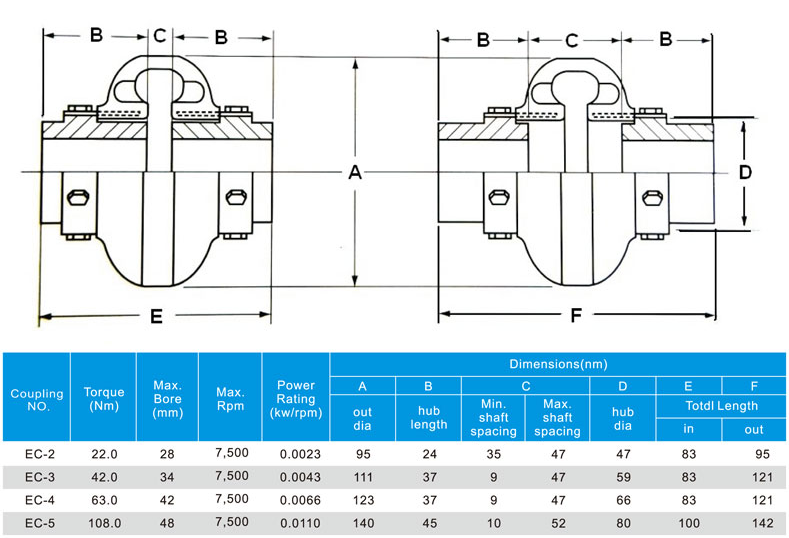

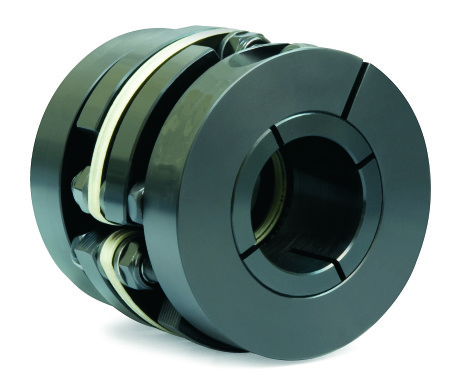

Flexible Gear Couplings basically consist of two hubs, with crowned external teeth and two outer sleeves with internal spur teeth.

Gear Hubs and the outer sleeves are manufactured from carbon steel and are hardened to the required degree. They are machined to fine tolerances for proper meshing of the gears as well as for inter-changeability.

flexible gear coupling

Gear Couplings belong to the category of flexible couplings that are capable of transmitting very high torques. Constructionally the gear coupling utilizes the advantages of gear engineering; practically the coupling is a complete gear assembly. Let us now look into the constructional aspects of the coupling.

- The gear couplings consists of a forged sleeve with internal teeth cut on its inside. The forged sleeves are normally two halves possessing internal gears in both of them. In certain cases the forged sleeve tends to remain a single piece.

- Two hubs with external teeth containing the same number of teeth as in the internal gear is present with each one being mounted on the driven and driver shaft respectively. The tooth profile of the external teeth is normally crowned in order to take up more loads.

Grid Coupling

Functions as a resilient coupling by damping torsional vibration and cushioning shock loads, resulting in reduced vibration at the output end of the coupling. Peak loading is reduced, for smooth torque transmission, to help protect connected equipment from potentially damaging vibratory loads. During an extreme overload, the grid can shear, reducing the possibility of damage to expensive machinery and equipment.

Elastomeric Coupling

The Elastomeric Coupling is a non-lubricated flexible coupling with benefits such as long life, simple installation, wrap around design, rubber in compression, cushions shock loads, corrosion resistant, and dampens torsional vibrations. Simple installation of this coupling is a unique feature. Just mount the hubs, align the shafts and install the flexible element. Assembly is completely visible, with no hidden or hard to reach components. The flexible element can be replaced without disturbing foundation bolts or shaft alignment. Bore Ranges from 1/2″ to 5 3/8”.

Gear Coupling

Lifetime all-metal end ring, provides up to 300% greater lubricant capacity. This means that longer periods between relubrication may be scheduled. It is the only coupling designed to use oil lubrication. Features of this coupling includes: The all-metal end ring, used exclusively in couplings, eliminates the need for any type of perishable lube seal.

About us

We are one of biggest Manufacturers and Suppliers in China, Choose Quality Manufacturers, Suppliers, Exporters at flexible-gear-coupling.xyz

flexible gear coupling

Describe Your BUYING Requirement

Tips on getting accurate quotes. Please include product name, order quantity, usage, special requests if any in your inquiry.